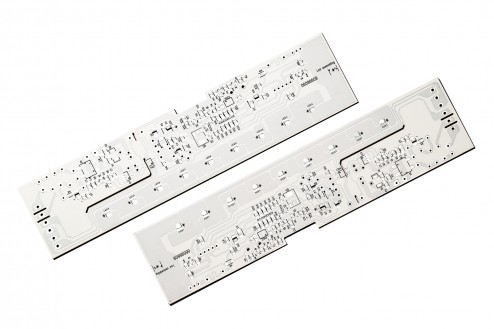

Cem 3 ht FR4 HTC

These are a valid alternative to aluminium substrates, with lower costs and the possibility of having a PCB with high dissipation capacity and metallized holes.

| CEM3 PCB REQUIREMENTS | CHARACTERISTICS |

| Number of layers | 1, 2 |

| Base material and thickness |

CEM-3 - thickness 1.6 mm |

| Thermal coefficient | 0.8 – 1.0 – 1.2 W/m°K |

| Min. track width/spacing | 0.200 mm |

| Insulation | 0.150 mm |

| Hole diameter | 0.200 mm |

| Base copper foil | 35μm / 1 ounce |

| Surface finish | Chemical Silver (AG) |

| Solder mask | Green, red, blue, black, yellow, transparent, white and high-reflectance white for LEDs |

| Silkscreen symbol colour | Green, red, blue, black, yellow, white |

| Minimum clearance between individual circuits shaped with a milling machine and/or arranged in a panel | > 2.0 mm (CNC shaping) |

| Minimum clearance between the outermost tracks for cutting circuit panel by means of V-cut scoring | > 0.4 mm with V-cut scoring |

| Production tests | Design Rule Check (DRC) |

| Electrical testing | Standard for all PCBs |