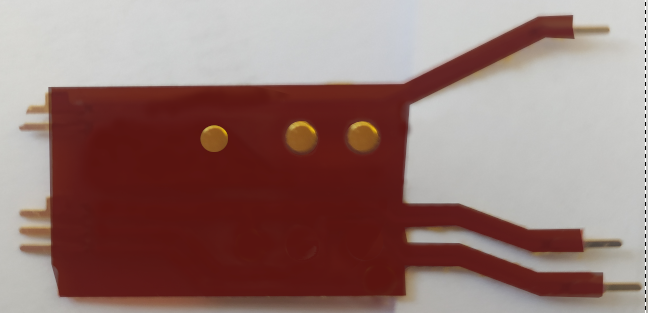

Flex PCB

We can manufacture flex PCBs of various thicknesses (from 25 microns to 300 microns) with different thicknesses of copper (17/35/70 microns).

A high-performance coverlay enables us to meet the most wide-ranging needs of designers.

The standard pad finish is silver, but chemical gold and chemical tin are also available to order.

To ensure that you select the right material, we advise you to contact our technicians, who will give you the necessary support to configure the ideal PCB for your requirements.

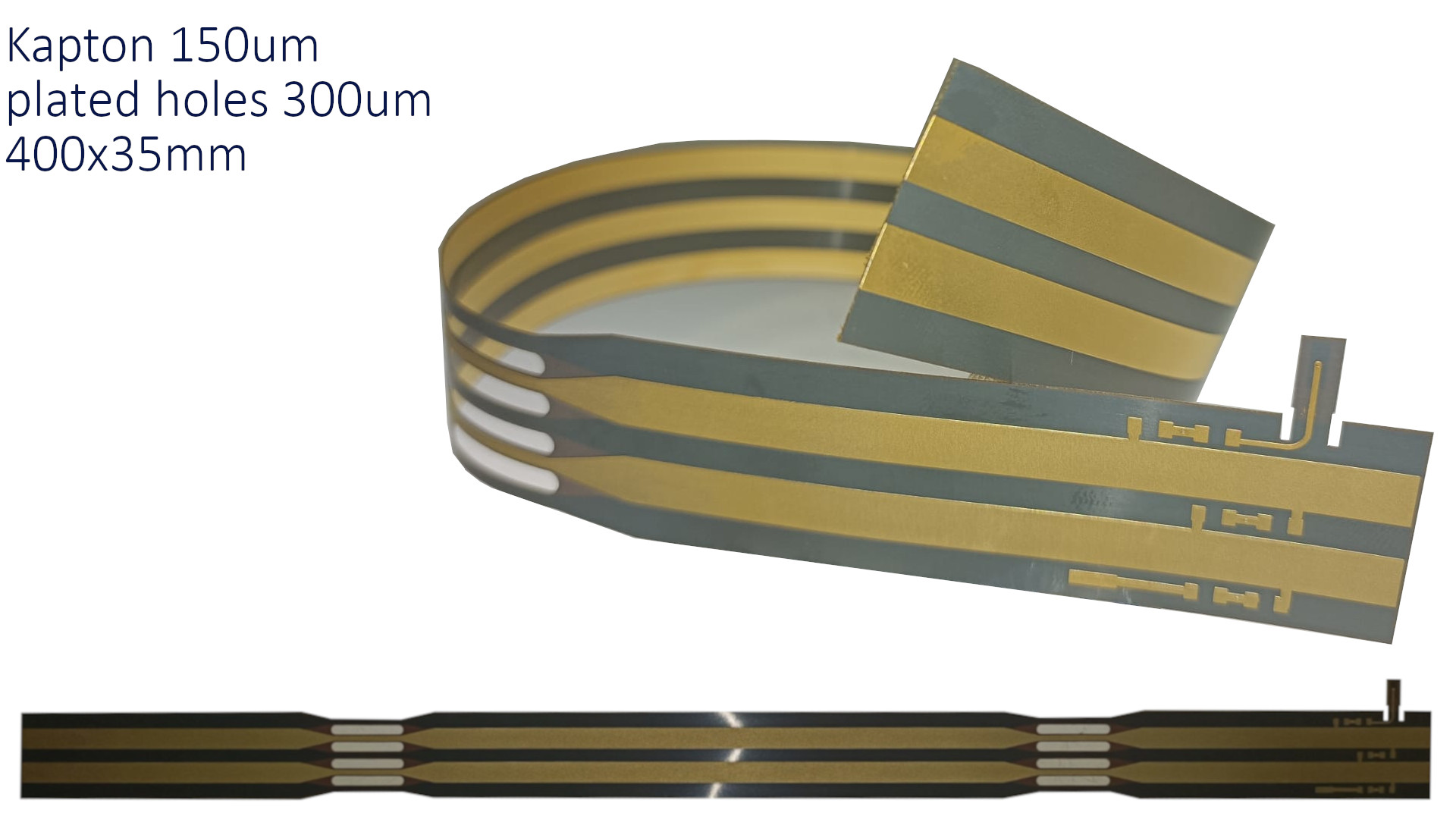

FLEX 200um - copper 200um - PIN 200um :

| REQUIREMENTS | CHARACTERISTICS |

| Number of layers | 1, 2, 4 |

| Base material |

Kapton |

| Thickness of base material | 25, 50, 125, 300 μm |

| Base copper (copper foil) outer layer | 17μm / ½ oz -35 μm / 1 oz |

| Base copper (copper foil) inner layer | 17μm / ½ oz -35 μm / 1 oz |

| Maximum PCB dimensions | 455 mm x 383 mm |

| Min. track width/min. insulation | 150 μm |

| Min. finished hole size | 200 μm |

| Minimum annular ring on outer layer with metallized or non-metallized hole | 0.250 mm - PTH / 0.250 mm - NPTH |

| Minimum annular ring on inner layer with metallized or non-metallized hole | 0.300 mm - PTH / 0.300 mm - NPTH |

| Minimum clearance between outermost track and edge of outer layer | 0.100 mm (routed) |

| Minimum clearance between outermost track and edge of inner layer | 0.200 mm (routed) |

| We consider slots and millings | > 2.0 mm or not round |

| Surface finish | Chemical silver (AG); selective Ni/Au (ENIG) |

| Soldermask | Specific coverlay |

| Silkscreen symbol colour | Green, red, blue, black, yellow, white |

| Minimum clearance between individual circuits shaped with a milling machine and/or arranged in a panel | > 2.0 mm (CNC shaping) |

| Minimum clearance between the outermost tracks for cutting circuit panel by means of V-cut scoring | > 0.4 mm with V-cut scoring |

| Electrical testing | Standard for all PCBs |